By: Brad Smith

The “hop back” is used by many micro and commercial brewers to add hoppy flavor and aroma to any beer. #Homebrewers can also take advantage of this technique with simple equipment to add additional aroma to home brewed beer.

Using a Hop Back

A hop back is a device that is inserted in line as the beer is transferred and cooled from the hot boiler into the fermenter. The main purpose of a hop back is to transfer delicate hop oils and aromas that would otherwise be boiled off in the boiler. The technique is used for many ales and related styles where a hoppy aroma is desirable.

Whole or plug hops are used in a hop back, as the goal of the device is to maximize surface contact between the hot wort and the hops. Typically 1-2 oz of hops are used for a 5 gallon home batch. The hop back is inserted at the hot end, closest to the boiler to maximize the transfer of hop oils. Little actual alpha bitterness is added by a hop back, as the wort is not boiling, but a lot of fragile hop oils and aromas can be added. Since aroma, and not bitterness, are the goal it is best to use low alpha aroma hop varieties in your hop back.

Commercial brewers often make dual use of the hops from their hop back. After the hops have been used in a hop-back, many of the fragile oils have been taken out but the high alpha bittering hop oils remain. Therefore brewers can take the hops used in the hop back and boil them to extract bitterness in a subsequent batch. While this is difficult for homebrewers to do unless they brew multiple batches in a day, some homebrewers have been able to reuse hops in this way when creating parti-gyle brews (more than one batch of beer from a single mash).

You can purchase small hopback device from many home brewing supply stores. These typically consist of a small watertight container that can be easily opened and sanitized before use. Hops are added to the container and it is sealed for use. An inlet tube and outlet tube flow the hot wort through the hop back, and then into either a counterflow chiller or other cooling device before the wort is transported to the fermenter.

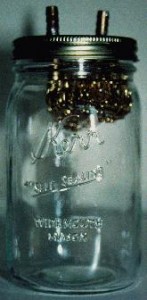

Making your own Hop Back

You can also build a hop-back at home from most any watertight heat resistant container. One of the more innovative home designs I’ve seen consists of nothing more than a ball canning jar with holes drilled into the top where tubes and fittings have been added to produce a watertight seal. An article on Bodensatz brewing (image shown above) has one of these devices that uses a copper or stainless steel put scrubber to help form a filter on the outgoing end of the hop back to prevent hops from plugging up the outlet hose. If you create such a device it is important to use lead-free solder when soldering the pieces together, and check the system to make sure it is watertight before use.

Your Beer, Your Way! Brew Like a Boss!

No comments:

Post a Comment