This item allows you to configure a 240 volt system just how you need/want it.

To configure a complete system, you will need to add the other components (Pump, Kettle, Heater Element, COFI Mash Filter, and any other optional accessories you may want).

This system includes the newest Brew-Boss V3 controller. This controller has a larger 20 character by 4 line back-lit LCD display that provides more information as well as makes the integrated fermentation mode more user friendly. it also includes a rotary switch that allows the user to manually control the heater and pump as well as brew without the need for the companion Android App. The controller is universal for all countries that have 208-240 volt power. No separate 120 volt input is required for the USA when used with our new universal voltage DC pumps. (Note, this controller only works with 208-240 volt pumps!). The new controller also has a dedicated always on 240 volt receptacle for powering/charging the tablet!

The V3

controller is supplied with 15 foot long 10 gauge cable for powering the unit with 240 Volts AC. The 240VAC power cable is supplied with a molded L6-30P twist lock plug. It is highly recommended that you install a Ground Fault Interrupter (GFI) type breaker on the circuit(s) you will be plugging the Brew-Boss into or use

our inline GFI unit. If you need a plug other than the L6-30P provided, you may simply cut the supplied plug off and connect a plug that matches your outlet.

The controller requires a 220-240 Volt circuit of at least 30 Amps with a GFI breaker (or our

inline GFI) installed to operate. The controller has a single 240 Volt L6-30R twist lock output receptacle that connects to a Brew-Boss Heater assembly or any other L6-30P heater (like the Blichmann Engineering Boil Coil). A digital temperature probe is included with this controller that plugs directly into the front of the controller.

The controller has a 20 character x 4 line back-lit LCD display that displays pertinent operational data as well as a rotary switch that allows the user to interact with the controller to manually control the heater and pump as well as brew in Stand-Alone mode.

If you desire a complete system, you must add the desired optional items (Kettle, Heater Element, Mash Method, and Optional Accessories). If you don't select any options, you will receive just the controller and temperature probe.

The Base Price Shown for this item is for the Brew-Boss

Controller and temperature probe only!

You will need an Android tablet with a 7" or larger screen to operate this controller/system. It must have a screen size of at least 7" (will not work on Android Phones!).

Note: We no longer sell Android Tablets with our systems. You will need an Android Tablet to run the Brew-Boss app on. We recommend a 10.1" screen or larger, but it will run on tablets with screen sizes 7" or larger. The app is not designed for phones and will not run on phones. If you don't have an Android tablet, we recommend

this one from Amazon or an

Amazon Fire tablet.

If you are installing this onto your own kettle, you will also need to add the

weldless direct connect temperature probe adapter from our Brewing Accessories page if you don't already have a thermowell on your kettle.

If you want a complete system, you must add the following items as well at a minimum:

- Heater Element Assembly

- Kettle

- COFI Mash Filter (same size as kettle)

Tip: You can click on the "Update Price" button to see your total cost as you add items.

Heater OptionsThe Brew-Boss Heaters are all stainless steel and designed by Brew-Boss especially for brewing.

The heaters clean very easily and look brand new after each brew session. The 5500 Watt is the most popular as it is the fastest. You must have at least a 30 AMP circuit if you plan on using this heater element. Some countries limit their 220-240 VAC circuits to 20 Amps. If you live in a country that limits you to 20 Amps, select the 3500 Watt heater Assembly. The cost of the 3500 Watt is slightly higher as our volume is not as great, so our pricing is a little more for that version. Also, if you want a 10 gallon system, you must order the 3500 Watt element. The 5500 Watt is simply too powerful and cannot be throttled down enough to maintain mash temperatures accurately. If you don't have 30 amps available, choose the 3500 Watt element, but only if you are purchasing a 10 or 15 gallon system. There is not enough heat capacity in the 3500 Watt heater for the 20 gallon kettle. The heater element options on this page include an 8 foot long L6-30 extention cable that plugs into the controller on one end and onto the element on the other,

Kettle OptionsThe kettles are complete and are supplied with TIG welded ferrules for the heater(s) and pump/output ports. They also include the Weldless Direct Contact Temperature Probe Mount. The 15 and 20 Gallon Kettles include electrically etched volume markings on the inside of the kettle.

20 Gallon Brew-Boss kettle with volume marking on the inside. Volume markings Included with all 15 and 20 gallon kettles. (sorry not available on 10 gallon kettles)

Each kettle is also equipped with an Accessory Port near the top of the kettle. This port has a Cam-Lock quick connect installed on both the inside and outside of the kettle to allow connection of the mash system hardware, optional Swiirl-Boss, or optional chiller. The kettle includes a cover/lid as well.

Brew-Boss Accessory Port

Brew-Boss Accessory PortThe 10 gallon kettle will accommodate batches up to 5 gallons. The 15 gallon kettle is designed for primarily 5 gallon batches but will do 10 gallon batches using the "Hybrid Method" discussed on our FAQ's page. The 20 gallon kettle will do 5 or 10 gallon batches and also 15 gallon batches if needed using the Hybrid method.

Make certain if you need a kettle to add it to your shopping cart in the options below.

Mash Hardware OptionsMashing is the brewer's term for the hot water steeping process which hydrates the barley, activates the malt enzymes, and converts the grain starches into fermentable sugars. The Brew-Boss system performs efficient mashing by continuously recirculating the wort during mashing through the grain bed, improving the efficiency over traditional Brew-In-A-Bag type systems. Recirculating the wort through the mash also creates a clearer wort, as the grain acts as a filter media as well. The Brew-Boss system provides two different methods for accomplishing the mashing task:

Brew-In-A-Bag (BIABag) Center-Out-Forced-Infusion (COFI, our patent pending mashing technology that can increase Efficiency)

The Brew-In-A-Bag (BIABag) Mash Option This mash option uses a stainless steel false bottom along with a mesh bag to contain the grains. A sparge/sprayer arm mounts directly to the accessory port on the kettle and provides even coverage of the grain bed with recirculated wort.

Brew-In-A-Bag Mash Option Showing False bottom, Sparge Sprayer Arm, and Mesh Bag Installed

The Brew-In-A-Bag Mash Option includes the following components:

- Stainless Steel False Bottom to Keep Bag from Touching Heater Element

- Copper Sparge/Sprayer Arm Connects to Recirculation Port on Kettle

- 24 Volt Brushless DC Brewery Grade Pump with Stainless Steel Pump Head (Can be excluded in Options)

- Stainless Steel Cam-Lock Fittings for Hose Connections

- Triclamp to Female NPT Adapter for Direct Mount of Pump to Kettle

- Stainless Steel Flow Regulation Ball Valve (You Install on Pump Discharge)

- TriClamp Gaskets and Clamps

- Brew-In-A-Bag Mesh Bag

- Stainless Steel Wing Nut Type Hose Clamps for Hoses on High Pressure Side of Pump

- 4' of Brewery Grade Silicone Tubing

- High Quality Teflon Pipe Thread Tape

The COFI mash Infusion Filter Option This mash option uses a Patent Pending stainless steel mesh basket (COFI Filter) to contain the grains. This mesh basket is also equipped with a cover that prevents grains from exiting the basket over the top edge during mashing. This allows higher flow rates during mashing which can provide more efficient conversion. Recirculated wort is delivered to the grains via a special center infusion tube that maximizes coverage of all grains inside the filter, creating a very steady temperature profile within the grain bed without the need for stirring. The COFI filter also includes a Patent Pending false bottom within the filter that allows the grains to be squeezed when they are removed like a reverse French Press. This assures maximum extraction of sugars trapped within the grains. This eliminates the need for a sparge.

It includes the following components:

- Stainless Steel Mesh COFI Infusion Filter

- False Bottom for COFI Filter with Center Infusion Tube

- 24 Volt Brushless DC Brewery Grade Pump with Stainless Steel Pump Head (Can be excluded in Options)

- 90 Degree Barbed Elbow Threads Onto Center Infusion Tube

- Stainless Steel Cam-Lock Fittings for All Hose Connections

- Stainless Steel Flow Regulation Ball Valve (Installed on Pump Discharge)

- TriClamp Gaskets and Clamps

- Stainless Steel Wing Nut Type Hose Clamps for Hoses on High Pressure Side of Pump

- 6' of Brewery Grade Silicone Tubing

- Stainless Steel Lift Ring for COFI Filter

- High Quality Teflon Pipe Thread Tape

COFI Filter Attached to Accessory Port

Other OptionsIn addition to the above options which are required for a complete system, we offer some options that allow you to enhance your Brew-Boss system.

Pick-Up Tube Kit - This durable Tri-Clamp pickup tube is constructed of beautiful polished 304 stainless steel. It attaches directly to the Tri-Clamp ferrule on the Brew-Boss kettle using a Tri-Clamp gasket and Tri-Clamp Clamp (

gasket and

clamp included). It allows you to drain nearly all of the wort out of your kettle without tipping the kettle and disrupting the trub on the bottom. Mount this between your kettle and valve or between your kettle and pump. Includes pick-up tube with 1.5" Tri-Clamp ferrules.

In-Line GFI - This is a portable In-Line GFI unit with L6-30 plugs already on it. This is handy if you do not have room in your home panel to add a GFI circuit breaker. it simply plugs into a L6-30 receptacle and the Brew-Boss controller plugs into it.

Hops-Boss - This is our patent pending automated hops feeder offered at a special reduced price if ordered with a system. Automatically adds your hops at the proper time.

Swirl-Boss - This is a nifty whirlpool device that mounts directly to the accessory port on the kettle and allows you to whirlpool your wort before transferring to your fermenter. Special reduced price when ordered with a Brew-Boss system.

Condenser-Boss Steam Condenser - If you brew indoors, you definitely want to consider adding this item to your order. This device simply connects to the accessory port on the kettle and to your cold water supply (tap water) and converts most of the steam generated during the boiling step into water. It allows you to brew inside without creating clouds in your home! It also reduces the amount of electricity required to maintain a boil, so it save energy and $$ as well.

90 Degree Pump Mounting Kit - This kit option includes a 90 degree elbow and an additional gasket and clamp to allow you to rotate the pump 90 degrees as shown in the main image for this item (the image with the system sitting on the brew stand). If you don't like the pump sticking straight out then order this add-on kit.

Accu-Fill Automated kettle Filler - This device attaches to the accessory port on the kettle and to your water supply. It automatically dispenses the proper amount of water into your kettle before brewing. it can be controlled by the Android App and included in your brew steps or used manually in stand-alone mode. This device is great for Brew-on-Premise operators, production breweries, or those that want cool automation!

Chiller - We have found this to be the best chiller on the market. The copper in Plastic design never plugs and provides very high cooling efficiency from your cold tap water. Much better design than flat plate chillers that are prone to plugging up and impossible to clean and much more efficient than immersion chillers.

Fast Ferment Fermenter - This is quite possibly the greatest fermenter ever designed. We use these exclusively in our Brew-On-Premise operation and they are awesome. They eliminate the need for a primary to secondary transfer (potential oxygen contact and contamination) and your retired yeast sediment never touches the beer you drink. They also make harvesting yeast for re-use a dream. Once you use a FastFerment you'll never wonder how you every got buy with carboys or buckets.

Trivet Set - These silicone trivets are great for placing your Brew-Boss kettle on to prevent heat transfer to your table or bench. The protect the surface and keep the kettle from accidentally being slid around, so they add safety as well. We sell these for less than our local Walmart does, so if you need them, add them to the system order.

Hoist - This is a really nice double line rope hoist that makes removing your grain bag, grain basket, or COFI filter very easy. It is auto locking so you don't have to tie it off or have someone else hold it. You'll need something to lift your grains out if you have a 15 or 20 gallon system. This hoist is the best we've found.plugs into it.

REMEMBER TO CONFIGURE YOUR

SYSTEM TO INCLUDE JUST THE CONTROLLER OR ALL COMPONENTS NECESSARY FOR A COMPLETE SYSTEM.

Your Beer, Your Way! Brew like a Boss!

#brewbosssystem,#electrichomebrewequipment,#240vbrew,#beer

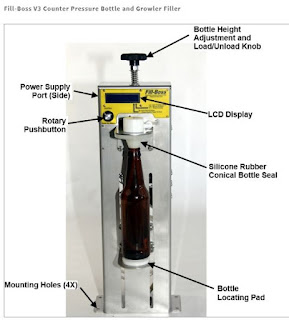

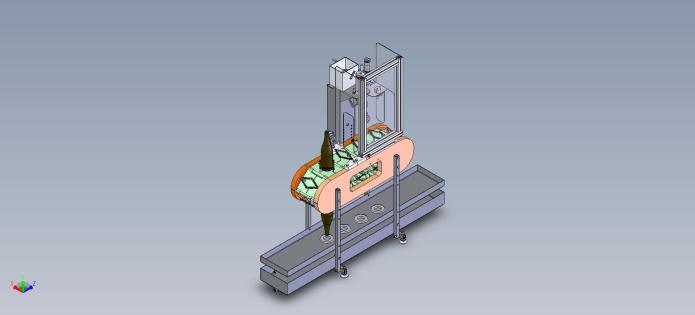

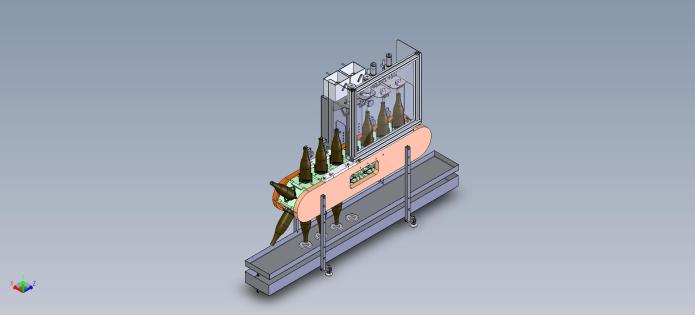

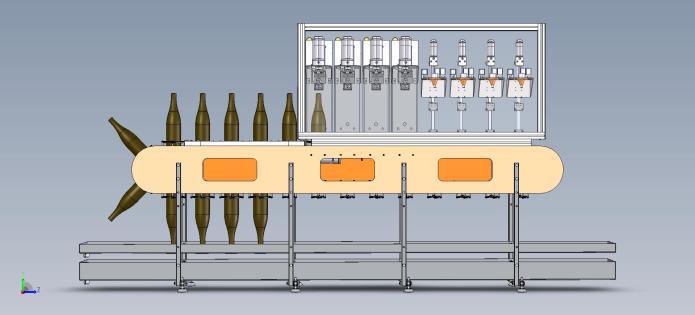

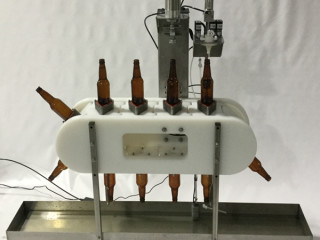

customers have asked us for a more automated system that also caps the bottle. Our Fill-Boss counter pressure bottle filler retails for 1/3 the cost of competing products, does way more, and has been our biggest seller. We've been working on a fully automated product design and several prototypes and after nearly 2 years we've built a functional prototype and want to release the product as quickly as we can. We call this new product

customers have asked us for a more automated system that also caps the bottle. Our Fill-Boss counter pressure bottle filler retails for 1/3 the cost of competing products, does way more, and has been our biggest seller. We've been working on a fully automated product design and several prototypes and after nearly 2 years we've built a functional prototype and want to release the product as quickly as we can. We call this new product